Why We Love Handmade Rugs

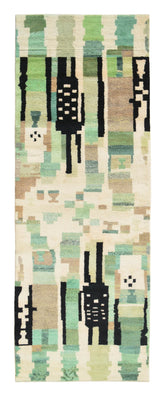

Handmade rugs have wide scale popularity all over the world. The tradition of rug making has been around for centuries and has continued today in the modern world. They have such a following that even interior designers frequently include them in their modern interior designs.

The beauty of these rugs stems from the incredible amount of time, hard work, and dedication that goes into making them. Machine-made carpets cannot come close to imitating the attractiveness found in handwoven rugs. Here’s a brief description of processes involved in handmade rugs, giving them the exquisiteness that we love.

Preparing Wool

The first step in making a quality rug is to prepare the wool. It begins with extracting wool from the local sheep and then shipping it by tons to headquarters, where it requires the aid of expert eyes. The fibers are separated by hand by shades of color, usually in 3 categories of light, neutral, and dark. The wool is also combed and cleaned of dust or foreign particles in a carding process. This process of preparing the wool is too complex for a machine.

The process can be made easier but has many drawbacks when it comes to machine-making the rugs. They can be made from synthetic materials that don’t need these time-consuming steps to separate and clean the natural wool. However, these synthetic materials can be toxic to the environment, not to mention the poor quality and incredibly basic designs in comparison to handmade rugs.

Dyeing process

The dyeing process of the wool also benefits from the irregularities of the hand. The inconsistent spread of the dye throughout, adds to the beauty of handmade rugs.

In the dyeing process, thousands of hues are possible. Larger dye jobs, those that require the color of the base, are handled by machines. The traditional way of hand dyeing in pots over an open fire is employed for jobs that require multiple colors (as most jobs do). The dyed wool is then dried in the open air and sent for weaving.

Looming Methods

All the previous processes were preliminary yet essential steps to prepare the wool for actual rug-making. Now, onto the main process where rugs are weaved. There are three main categories of rugs according to looming patterns.

- Hand-Loomed

Hand-looming the rugs is the least expensive method of the three. A tool called a “wooden loom” is used by workers, who must work together in perfect harmony to make the rug.

- Hand-Tufted

This method enables the etching of more complex patterns unable to be engraved by hand-looming. It takes years to become an expert, and even then, it takes at least ten days to complete a 5x8 foot small rug.

- Hand-Knotted

This is the most expensive of the three and requires the highest skill level. This method enables the etching of the most intricate of patterns. It is not unusual to take up to 2 years to prepare a rug via hand-knotting.

Finishing and Shipping

The completed rugs are hand-washed in pure water and dried under natural sunlight. After drying, they are stretched into a symmetrical shape. Some rugs may then be hand-carved to create beautiful 3D patterns.

The process of creating a rug requires incredible attention to detail and an astonishing amount of effort. However, that is the exact reason why these rugs turn out to be amazingly classy and stylish. If you want to acquire these rugs for yourself, visit illuminatecollectiverugs.com.